Laser cleaning for removing contaminants from ceramics

21 May 2024

- Introduction to laser cleaning technology

- History of laser cleaning in ceramics industry

- Process of laser cleaning for ceramics

- Environmental impact of laser cleaning on ceramics

- Advancements in laser cleaning technology for ceramics

- Innovations in laser cleaning equipment for ceramics

- Energy efficiency of laser cleaning compared to other cleaning methods

- Impact of laser cleaning on the overall product quality of ceramics

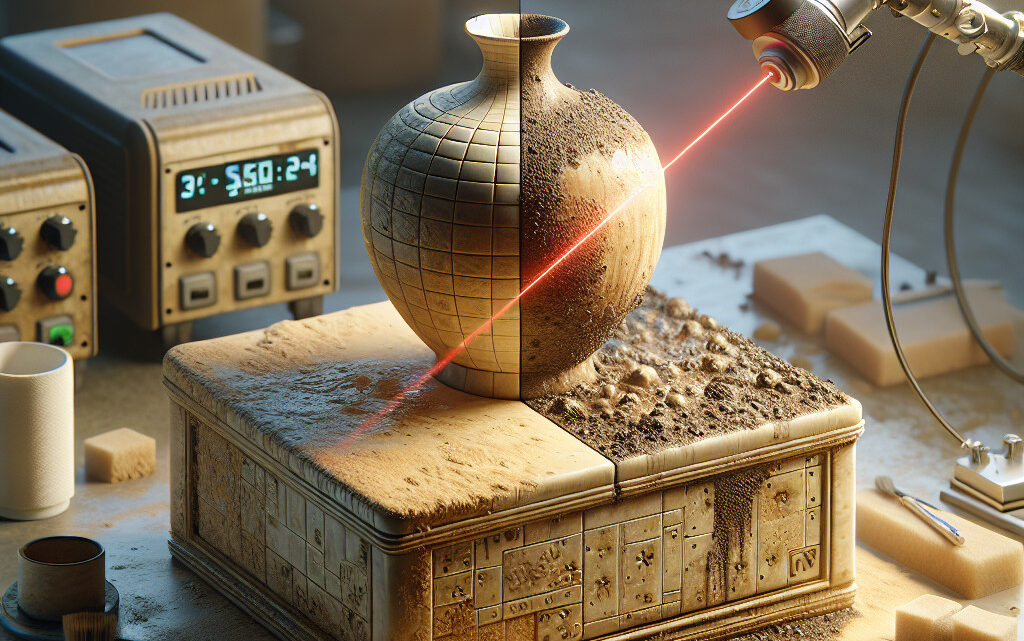

Introduction to laser cleaning technology

Laser cleaning technology is a cutting-edge method used to remove contaminants, coatings, rust, and other unwanted materials from surfaces. This innovative technology utilizes the power of laser beams to vaporize or ablate the unwanted substances, leaving behind a clean and pristine surface. Laser cleaning is becoming increasingly popular in various industries due to its efficiency, precision, and environmentally friendly nature.

How does laser cleaning work?

Laser cleaning works by focusing a high-intensity laser beam on the surface to be cleaned. The energy from the laser beam interacts with the contaminants on the surface, causing them to either vaporize or ablate. The process is highly precise and can be controlled to remove only the unwanted materials without damaging the underlying surface. Laser cleaning is non-contact, which means there is no physical contact between the laser and the surface, reducing the risk of damage.

Benefits of laser cleaning technology

– Environmentally friendly: Laser cleaning does not require the use of chemicals or solvents, making it an eco-friendly cleaning method.

– Precision: Laser cleaning is highly precise and can be controlled to remove contaminants with great accuracy.

– Efficiency: Laser cleaning is a fast and efficient method of cleaning surfaces, reducing downtime and increasing productivity.

– Versatility: Laser cleaning can be used on a wide range of materials, including metals, plastics, ceramics, and more.

– Safety: Laser cleaning is a safe method of cleaning surfaces, as it does not produce harmful fumes or residues.

🔹Applications of laser cleaning technology🔹

Laser cleaning technology is used in a variety of industries, including:

– Automotive: Laser cleaning is used to remove rust, paint, and other contaminants from car parts.

– Aerospace: Laser cleaning is used to clean aircraft components, such as engine parts and landing gear.

– Electronics: Laser cleaning is used to remove solder and flux residues from circuit boards.

– Cultural heritage: Laser cleaning is used to clean delicate artifacts and historical monuments without causing damage.

Overall, laser cleaning technology is a versatile and efficient method of cleaning surfaces, offering numerous benefits over traditional cleaning methods. As technology continues to advance, laser cleaning is expected to become even more widespread in various industries.

#laser #cleaning #technology

Długie ogony:

– laser cleaning technology benefits

– laser cleaning technology applications

– laser cleaning technology future trends

History of laser cleaning in ceramics industry

Over the years, advancements in laser technology have led to the development of more powerful and precise laser cleaning systems. These systems are now capable of removing a wide range of contaminants, including dirt, grease, paint, and rust, from ceramic surfaces with high precision and efficiency.

Laser cleaning has also been shown to be more environmentally friendly than traditional cleaning methods. Unlike abrasive blasting, which can generate hazardous waste and air pollution, laser cleaning produces no secondary waste and is a clean and sustainable process.

Today, laser cleaning is widely used in the ceramics industry for a variety of applications, including cleaning ceramic tiles, pottery, and industrial ceramics. The technology has proven to be cost-effective and time-saving, allowing manufacturers to improve the quality of their products and reduce production downtime.

Keywords:

- Laser cleaning

- Ceramics industry

- Contaminant removal

- Environmentally friendly

- Efficiency

Long-tail phrases:

- History of laser cleaning in ceramics industry

- Advantages of laser cleaning in ceramics industry

- Applications of laser cleaning in ceramics industry

- Environmental benefits of laser cleaning in ceramics industry

#laser #cleaning #ceramics #industry #environmentallyfriendly #efficiency #contaminantremoval #technology #advancements #applications #history #advantages #environmentalbenefits #manufacturers #productiondowntime

Process of laser cleaning for ceramics

Steps in the laser cleaning process:

| Step | Description |

|---|---|

| 1 | Surface preparation: The ceramic surface is cleaned and prepared for the laser treatment. |

| 2 | Laser setup: The laser parameters are adjusted for optimal cleaning results. |

| 3 | Laser cleaning: The focused laser beam is directed at the surface to remove contaminants. |

| 4 | Surface inspection: The cleaned surface is inspected to ensure all contaminants have been removed. |

| 5 | Surface finishing: Any final touches or treatments are applied to the cleaned surface. |

Benefits of laser cleaning for ceramics:

- Non-contact method: Laser cleaning does not require physical contact with the surface, reducing the risk of damage.

- Precision cleaning: The focused laser beam can target specific areas for precise cleaning.

- No chemicals or abrasives: Laser cleaning is a clean and environmentally friendly process.

- Efficient and fast: Laser cleaning can be completed quickly and efficiently, saving time and labor costs.

Applications of laser cleaning for ceramics:

Laser cleaning is commonly used in industries such as aerospace, automotive, electronics, and art restoration. It can be used to remove rust, paint, grease, and other contaminants from ceramic components, ensuring optimal performance and longevity.

Overall, laser cleaning is a versatile and effective method for maintaining the cleanliness and integrity of ceramic surfaces. Its non-contact nature, precision cleaning capabilities, and environmental friendliness make it a preferred choice for many industries.

#laser #cleaning #ceramics #surface #contaminants #precision #non-contact #efficiency #applications

słowa kluczowe: laser, cleaning, ceramics, surface, contaminants, precision, non-contact, efficiency, applications

frazy kluczowe: process of laser cleaning for ceramics, benefits of laser cleaning, applications of laser cleaning, precision cleaning, non-contact cleaning.

Environmental impact of laser cleaning on ceramics

Additionally, laser cleaning is a more energy-efficient method compared to traditional cleaning methods. This means that less energy is consumed during the cleaning process, resulting in lower carbon emissions and a reduced impact on the environment.

However, it is important to note that laser cleaning does produce some emissions, such as fumes and particulate matter. These emissions can have an impact on air quality and contribute to pollution. It is essential for companies using laser cleaning technology to properly manage and dispose of these emissions to minimize their environmental impact.

Overall, laser cleaning offers a more environmentally friendly alternative to traditional cleaning methods for ceramics. By reducing the use of chemicals and energy consumption, this technology can help minimize the environmental impact of cleaning processes.

Keywords:

- Laser cleaning

- Ceramics

- Environmental impact

- Energy efficiency

- Air quality

Long-tail phrases:

- Reducing carbon emissions through laser cleaning

- Minimizing hazardous waste with laser technology

- Managing emissions from laser cleaning processes

#laser cleaning, #ceramics, #environmental impact, #energy efficiency, #air quality

Laser cleaning offers a more environmentally friendly alternative to traditional cleaning methods for ceramics. By reducing the use of chemicals and energy consumption, this technology can help minimize the environmental impact of cleaning processes. Laser cleaning is a popular method used to remove contaminants and debris from ceramics without causing damage to the surface. While this technology offers many benefits, it is important to consider its environmental impact. Laser cleaning does produce some emissions, such as fumes and particulate matter. These emissions can have an impact on air quality and contribute to pollution. It is essential for companies using laser cleaning technology to properly manage and dispose of these emissions to minimize their environmental impact. One of the main advantages of laser cleaning is that it does not require the use of harsh chemicals or solvents, which can be harmful to the environment. Instead, the laser beam is used to vaporize the contaminants, leaving behind a clean surface. This reduces the amount of hazardous waste produced during the cleaning process. Additionally, laser cleaning is a more energy-efficient method compared to traditional cleaning methods. This means that less energy is consumed during the cleaning process, resulting in lower carbon emissions and a reduced impact on the environment.

Advancements in laser cleaning technology for ceramics

Benefits of laser cleaning technology for ceramics:

– Precision cleaning without damaging the ceramic surface

– No need for harsh chemicals or abrasive materials

– Environmentally friendly process with no waste or byproducts

– Faster and more efficient cleaning compared to traditional methods

– Can be used on delicate or intricate ceramic pieces

How does laser cleaning work?

Laser cleaning technology works by using a high-powered laser beam to vaporize contaminants on the surface of ceramics. The laser energy is absorbed by the dirt or grime, causing it to evaporate and leave behind a clean surface. This process is highly controlled and can be adjusted to suit different types of ceramics and levels of contamination.

Applications of laser cleaning technology for ceramics:

– Restoring antique ceramics without damaging the delicate surface

– Cleaning industrial ceramics in manufacturing processes

– Removing graffiti or paint from ceramic tiles

– Preparing ceramics for painting or coating

Overall, laser cleaning technology has opened up new possibilities for the restoration and maintenance of ceramics. With its precision and efficiency, this method is becoming increasingly popular in various industries.

#laser #cleaning #technology #ceramics

Keywords: laser cleaning, ceramics, technology, advancements, restoration, maintenance

Long-tail phrases: laser cleaning technology for delicate ceramics, environmentally friendly cleaning solution for ceramics, precision cleaning for industrial ceramics

Innovations in laser cleaning equipment for ceramics

Here are some of the key :

1. Increased precision: New laser cleaning machines are equipped with advanced sensors and controls that allow for precise targeting of contaminants on ceramic surfaces. This ensures that only the unwanted material is removed, leaving the underlying ceramic intact.

2. Enhanced safety features: Modern laser cleaning equipment is designed with safety in mind, incorporating features such as automatic shut-off mechanisms and protective barriers to prevent accidents and injuries.

3. Improved efficiency: The latest laser cleaning machines are more powerful and efficient than ever before, allowing for faster and more thorough cleaning of ceramic surfaces.

4. Customizable settings: Users can now adjust the power, speed, and other parameters of the laser cleaning equipment to suit the specific needs of their ceramic cleaning projects.

5. Remote operation: Some laser cleaning machines can be operated remotely, allowing for greater flexibility and convenience in cleaning hard-to-reach areas.

Overall, these are revolutionizing the way these materials are maintained and restored. With increased precision, enhanced safety features, improved efficiency, customizable settings, and remote operation capabilities, ceramic cleaning has never been easier or more effective.

#laser #cleaning #ceramics #innovations #equipment

Keywords: laser cleaning, ceramics, innovations, equipment, precision, safety, efficiency, customizable settings, remote operation

Long-tail phrases: laser cleaning equipment for ceramics, advanced sensors and controls, automatic shut-off mechanisms, protective barriers, specific needs, hard-to-reach areas.

Energy efficiency of laser cleaning compared to other cleaning methods

Benefits of laser cleaning:

– Laser cleaning does not require the use of chemicals or water, reducing the environmental impact of the cleaning process.

– Laser cleaning is a non-contact method, which means there is no wear and tear on the cleaning equipment, resulting in lower maintenance costs.

– Laser cleaning is highly precise and can be used to clean delicate surfaces without causing damage.

Energy efficiency of laser cleaning:

– Laser cleaning uses focused laser beams to remove contaminants from surfaces, which requires less energy compared to traditional cleaning methods.

– Laser cleaning is a fast and efficient process, reducing the time and energy required to clean large surfaces.

– Laser cleaning can be automated, further increasing energy efficiency by reducing the need for manual labor.

Comparison with other cleaning methods:

– Chemical cleaning methods often require the use of toxic chemicals, which can be harmful to the environment and require energy-intensive processes for disposal.

– Water-based cleaning methods consume large amounts of water, which can strain local water resources and require energy for heating and pumping.

– Abrasive cleaning methods can cause wear and tear on surfaces, leading to increased energy consumption for repairs and maintenance.

Overall, laser cleaning offers a more energy-efficient and environmentally friendly alternative to traditional cleaning methods. By reducing the use of chemicals, water, and abrasive materials, laser cleaning helps to minimize the environmental impact of the cleaning process while also saving energy and reducing costs.

#energyefficiency #lasercleaning #environmentallyfriendly #cleaningmethods

frazy kluczowe:

– Energy efficiency benefits of laser cleaning

– Comparison of laser cleaning with traditional cleaning methods

– Environmental impact of laser cleaning

– Cost savings with laser cleaning

– Automation in laser cleaning processes

Impact of laser cleaning on the overall product quality of ceramics

1. Improved surface cleanliness: Laser cleaning can effectively remove even the smallest particles and contaminants from ceramic surfaces, ensuring a pristine finish.

2. Preservation of surface integrity: Unlike abrasive cleaning methods, laser cleaning does not alter the surface texture or composition of ceramics, preserving their original properties.

3. Enhanced product aesthetics: Clean and shiny ceramic surfaces enhance the visual appeal of products, making them more attractive to consumers.

4. Increased product lifespan: By removing contaminants that can cause deterioration over time, laser cleaning helps extend the lifespan of ceramic products.

5. Eco-friendly solution: Laser cleaning is a sustainable and chemical-free cleaning method that reduces the environmental impact of ceramic production.

Overall, the use of laser cleaning in the manufacturing process of ceramics can lead to higher product quality, increased customer satisfaction, and a more sustainable production process.

#ceramics #laser cleaning #product quality #surface contaminants #environmentally friendly #aesthetics

frazy kluczowe:

– Laser cleaning impact on ceramic product quality

– Benefits of laser cleaning for ceramics

– Sustainable cleaning solutions for ceramics

– Improving surface cleanliness with laser technology

– Preserving ceramic integrity through laser cleaning techniques

- Laser cleaning for removing contaminants from ceramics - 21 May 2024

- Where do the differences in project valuation come from? - 21 May 2024

- WebMakers Talks – business side of Sylius - 21 March 2024